Hose Pros 101: The Basics – What Goser Teaches Your First Day on the Job

Hose Pros 101

Do you need to learn the basics of hose and how they’re used in industry? Maybe you need to train a new maintenance technician, maybe you need an engineer fresh out of college to understand how hydraulic hose systems work, or maybe you’re just curious and want to know about hose. This article is for you. In fact, we just hired an engineer with 20 years’ experience, and even he can learn something from this article. When it comes to the hose industry, understanding the various applications and hose constructions is vital to speccing the proper hose for your job.

Hose Construction

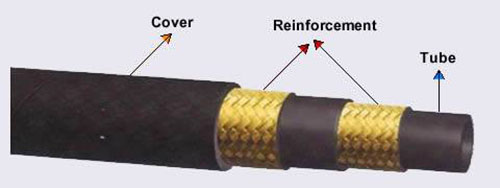

A hose is commonly made up of a tube, reinforcement, and a cover. This is a technicality, but if there is no reinforcement, then it’s just called tube or tubing. This is most seen with plastics. But if it’s got reinforcement, it’s a hose, and it’s what we’re talking about in this article.

Hose is typically broken into five categories: hydraulic, industrial, metal, Teflon (PTFE, fluorocarbon tube), and composite. Metal, Teflon, and composite are designated by their construction. Metal is made entirely of stainless steel or other non-corrosive metals, Teflon is made of Teflon, and composite is hose made of distinct, individual layers.

Tube

Working our way from the inside out, the tube’s job is to convey material, so it must be chemically compatible with what’s going through the hose and able to handle specific temperatures. It also must be nearly impermeable and capable of holding pressure. I say “nearly impermeable” because all material permeates at some rate. Think about your car tires. They hold air for months, but eventually need filled up to keep them at the right pressure. This is the permeation we’re talking about. It’s not often an issue with hose, but it’s something to be aware of. Metal is the closest to impermeable and some plastics perform well too.

Reinforcement

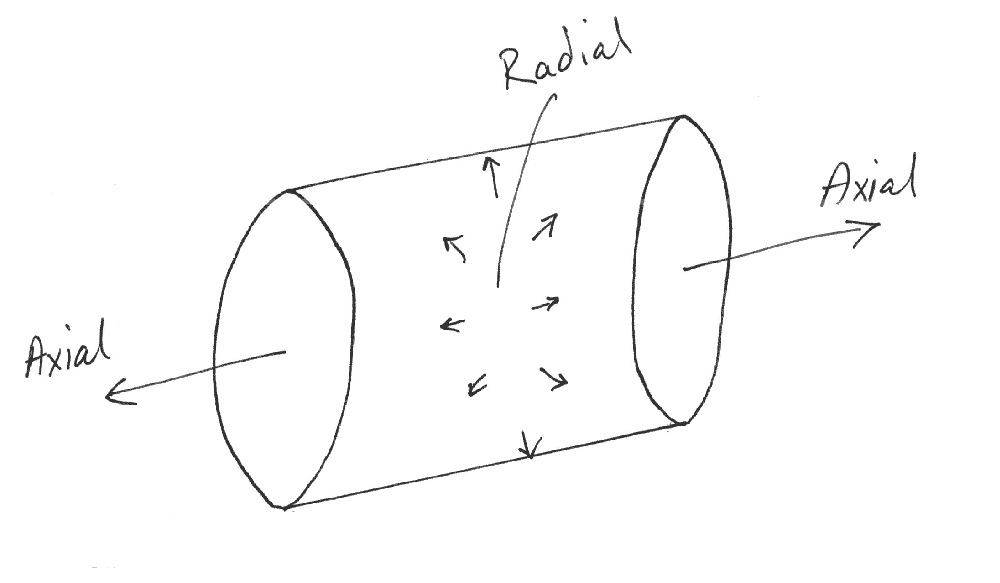

The tube is supported by the reinforcement, which is the backbone of hose, and supplies its strength and pressure capability. It comes in many shapes, sizes, and materials, the most of common of which are high tensile steel wire, textiles, and synthetics. Some specialty materials even include Kevlar, the stuff they make bullet proof vests from. It is wrapped around the hose in either a braided or spiraled configuration. This allows the hose to hold pressure that is both pushing out radially and axially.

Braid and spiral reinforcement give the hose positive pressure carrying capability, while a helix works in the other direction, when there is a negative pressure in the hose. A helix is made of metal or hard plastic and acts to keep the hose round when the pressure inside is acting to collapse the hose, especially important in suction applications.

Cover

The cover is applied over the reinforcement and acts to protect it from abrasion and corrosion. Covers must be able to withstand outside temperatures, abrasion, impact, ozone, industrial chemicals, and anything else that can harm the reinforcement. A good example of the importance of the cover is a hydraulic hose with a small nick in the cover, which may not seem like a big deal … until later that year when the steel braid rusts and becomes weak from corrosion. When that hose blows, it will blow at the spot that’s been damaged.

Covers are oftentimes supplemented with added accessories like fiberglass and silicone sleeves for temperature, or plastic or steel wrap to aid in abrasion resistance. Whatever part of the environment may harm your hose needs accounted for, and the cover is what is going to protect it. We can always add layers of protection if the off-the-shelf construction is not enough.

Metal and Teflon hose have no cover by design. They use a stainless-steel braid reinforcement so corrosion is rarely a concern. Since it is metal on the outside, people often think of it as a “tough” hose. Don’t be fooled by this misconception. Those wires are tiny, maybe .015” thick and sometimes less. If you let a metal hose drag on the concrete and those wires get ground from .015” to .005”, then guess where the hose will break … right there at the spot it was dragged.

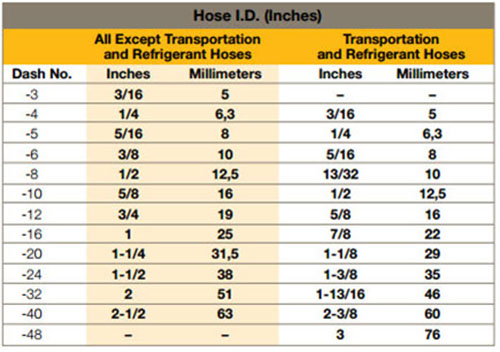

ID / OD

Hose is defined by its I.D., or inside diameter. For example, a 1” hose has a 1” inside diameter. When measured with calipers it will be pretty close to 1.00”. I say this because other industrial materials like tube and pipe are different. 1” pipe is neither 1” I.D. or 1” O.D. (outside diameter), but it’s close, 1.05” for Sch. 40 pipe I.D. and a 1.315” O.D. Tube, as we mentioned earlier, is measured by its O.D.

When we talk about hose size, especially hydraulic hose, we talk in terms of 16ths. A -12 hose, read “dash twelve”, is ¾” because 12/16=3/4.

OD is important because, when coupled with I.D., it gives us the wall thickness of the hose. Wall thickness is important because we use it to determine crimp diameters for industrial hose assemblies, where the fabrication is part science, part art, because the fabricator is determining the crimp size, and it can be different on the same hose assembly. Yes, you read that correctly. Wall thickness can vary enough throughout the hose that crimps made on two ends of one hose can have differing crimp diameters, while still maintaining the same compression ratio. Compression ratio is how much we compress the wall of the hose between the ferrule and the hose barb. Compressions of as little as 12% and as much as 22% are not uncommon. This is where the art part comes in to play, knowing when to be closer to 12% or closer to 22%. Things like the hardness of the hose compound and how the hose reacts when crimped need to be considered. Some larger diameter hoses can vary by ⅛” wall thickness in the same hose.

For hydraulic hose, it must be precise and consistent, because the specs for crimp diameters have a tolerance of +/- .005”. This implies the I.D./O.D. are kept to a tight tolerance so the crimps can also be held to a tight tolerance.

A Hose for Every Application

When you start looking through hose catalogs, one thing becomes apparent very quickly … there seems to be a hose for every application. In a hydraulic hose catalog, there are textile reinforced and steel reinforced hose constructions—one wire, two wire, four wire and six wire—rubber compounds for high heat and compounds for the Arctic, and compounds for corrosive hydraulic fluid, and on and on. And that’s just the hydraulic hose catalog. Then there’s the Industrial hose catalog, it has WAY MORE options for specific applications: steam, superheated steam, water suction, water discharge, air, high pressure air, sand blast, concrete … you get what I’m saying. The catalog is huge, and they all have a specific construction to address a specific application.

STAMPED – Selecting the Right Hose

We use the acronym S.T.A.M.P.E.D. to help determine which hose is the best one for a given application. Size, Temperature, Application, Media, Pressure, Ends, Details. If you can answer all those criteria, then you will be well on your way to the best hose. Check out our full blog post to get details.

A Word on Pressure and Working Pressure

The hose industry typically uses a safety factor based on burst pressure to determine a hose’s working pressure. The most common safety factor is 4:1. This means a 4,000-psi hose will burst at over 16,000 psi in a test. Other common safety factors are

- 10:1 for steam

- 3:1 for water

- 2:1 for hydraulic jacks

Manufactures will also play with safety factors to make their hose appear “better” or more capable than a competitor’s hose. It’s not frequent, but it’s definitely common. Be aware that sometimes the same hose (essentially) produced by two different manufacturers can have different working pressures, because one tests this way and the other that way, or they have engineering departments that simply take a different approach. What I’m saying is it’s not black and white, sometimes it’s gray.

Hose Life

Like any industrial product, a hose has a life expectancy. Some applications may only give the user a few weeks or months, like carbon injector hose or abrasive material handling. The application chews up the tube so fast it’s normal to have to replace it regularly. When the finance people see the frequency of replacement, they begin pushing for other solutions like ceramic lined tubes that are crazy expensive, but worth it, because they extend the life of the hose. Other factors, like temperature and corrosion, will also shorten the life of a hose. Another situation, sometimes unexpected, is when you max out two constraints of the hose, such as pressure and temperature. If you run the hose at max pressure and max temperature (or any other maxed out condition) it seems to really reduce life expectancy. Specs do not exist independently. If you’re pushing it on more than one aspect of the hose, consider upgrading to get more life.

Safety

It goes without saying that hose safety, proper construction, and specification are important, but let’s say it. Some applications are obviously dangerous: hazardous chemical transfer, bull hose on a compressor, hydraulic hose on a lift supporting a worker, to name a few. But even a ⅜” air line in a garage can whip if an end blows off and it can hit you pretty hard. At the beginning of a hose’s life it needs to be specced right and built properly. Once in use it needs to be examined regularly and taken out of service once there is damage or after its known service life is up.

Hope you found this article valuable and enjoyed Hoser’s Hose Pro insights.

TCH Industries

Our focus and obsession is the distribution and fabrication of hose for industry and hose related products. Founded nearly 40 years ago, we are proudly owned and operated by the same family. Our manufacturing partners are some of the biggest and best names: Eaton, Parker, Dixon Valve, Hose Master, Brennen, Hannay Reels, and many others.

In short, we are a customer-centric hose company filled with happy professionals who can help you meet all your hose related needs. If you have any questions, please reach out to us by filling out the form below!