Hydraulic Fittings

HOW TO IDENTIFY HYDRAULIC FITTINGS

Hydraulic systems are dependent on fluid ports, connectors, and threaded adapters to create a proper seal. Being positive that you have identified the proper hose fittings and adapters for your application is crucial to having a safe and effective system.

Choosing the wrong type of connection can impair the ability to seal, leading to system damage, leakage, and device failure. Not only can this damage equipment, but it can also be harmful to the operator.

Maintenance technicians and engineers can avoid these issues by using the fast, proven method of identifying the proper hydraulic fittings presented in this blog.

WHAT ARE THE DIFFERENT TYPES OF HYDRAULIC FITTINGS?

- American Connections

- NPT: National Pipe Taper is a general-purpose tapered pipe thread.

- NPTF: National Pipe Taper Fuel is a dryseal tapered pipe thread.

- NPSM: National Pipe Straight Mechanical is a straight-thread.

- SAE O-ring boss: Multipurpose thread for medium- and high-pressure hydraulic applications, where the O-ring is seated at the base of the threads.

- O-ring face seal: Straight thread fittings with a machine groove in the face of the fitting to accept and O-ring.

- JIC: Flared fitting machined with a 37° flare seating surface.

- Metric

- Metric compression:

- Metric O-ring boss

- Metric taper

- British

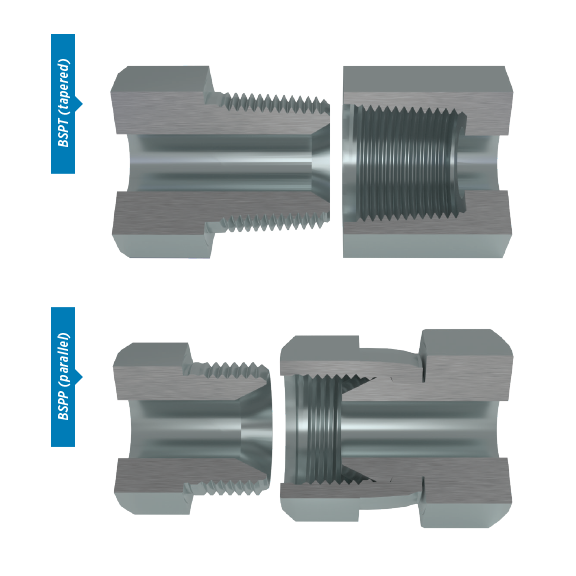

- BSPP: British Standard Parallel Pipe is a parallel thread fitting with a bonded seal O-ring.

BSPT: British Standard Pipe Taper is similar to NPT; however, the thread angle from root to crest is 55° instead of 60°

- Japanese

- JIS: Japanese Industrial Standard is a tapered pipe thread that is identical to and interchangeable with BSPT connections. The Japanese male thread does not have a 30° flare and will not mate with the BSPP female connection.

HOW DO I INDENTIFY HYDRAULIC FITTINGS?

Misidentifying threads can lead to wasted time and dangerous, improper connections. The first question you should ask yourself when identifying a connection is simple: What is the sealing mechanism?

- Is it a cone-shaped seal? – JIC, SAE 45, NPSM, BSPP, JIS, Metric Compression, Komatsu, Metric Ball Seat.

- Is there an O-ring? – O-ring face seal, SAE O-ring Boss, Code 61 & Code 62 4-Bolt Flange, Metric O-ring Boss, BSPP.

- Is the thread tapered? – NPT, BSPT, or Metric Taper

WHAT DO THE NUMBERS ON HYDRAULIC FITTINGS MEAN?

Some fittings will be stamped with a number. We refer to these as a dash size, which indicates the connection size. Keep in mind these numbers are all relative to 1/16”. For example, a -8 fitting is 8/16, or 1/2″.

| DASH | CONNECTION | DASH | CONNECTION |

| -2 | 1/8″ | -4 | 1/4″ |

| -6 | 3/8″ | -8 | 1/2″ |

| -10 | 5/8″ | -12 | 3/4″ |

| -16 | 1” | -20 | 1.25” |

| -24 | 1.5” | -32 | 2” |

We Are Hosers.

Our focus and obsession is the distribution and fabrication of hose for industry and hose related products. Founded nearly 40 years ago, we are proudly owned and operated by the same family. Our manufacturing partners are some of the biggest and best names: Eaton, Parker, Dixon Valve, Hose Master, Brennan, Hannay Reels, and many others.

In short, we are a customer-centric hose company filled with happy professionals who can help you meet all your hose related needs.

We Are Hosers.

Our focus and obsession is the distribution, fabrication, and manufacturing of hose assemblies for industry and hose related products. Founded nearly 40 years ago, we are proudly owned and operated by the same family. Our manufacturing partners are some of the biggest and best names: Eaton, Parker, Dixon Valve, Hose Master, Brennan, Hannay Reels, and many others.

In short, we are a customer-centric hose company filled with happy professionals who can help you meet all your hose related needs.