SELECTING THE RIGHT CHEMICAL HOSEWith the extensive list of chemicals used in industry, it is crucially important to select the right chemical hose for your application. Applications that utilize chemicals call for extra precautions and safety...

TCH Insights

Selecting the Right Hydraulic Hose

SELECTING THE RIGHT HYDRAULIC HOSETCH has a 40-year track record of helping companies with their most demanding hose assembly needs. Let’s just say we know a thing or two when it comes to selecting the right, high quality hydraulic hose for you....

Hydrostatic Testing

Hydrostatic TestingIn this blog, TCH Industries is going to be going over what is hydrostatic testing for a hose, how does hydrostatic testing work, and how to preform a hydrostatic test. What is Hydrostatic Testing for a Hose?Hydrostatic testing...

Hose Length Tolerance

Hose Length ToleranceThe Hose Pro's at TCH Industries explain what are the tolerances in hydraulic hose lengths, and how to proporly measure hose assemblies. Tolerances in Length of Hydraulic Hose AssembliesUnless specified by your customer,...

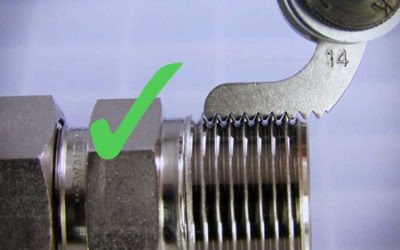

How to Identify the Right Threaded Connection

Hydraulic systems depend on fluid ports, connectors, and thread adapters to appropriately seal the equipment. Correctly identifying the right thread or connection type is critical to making sure that your hydraulic seals function properly, thus...

Metal Hose Selection Guide

The term metal hose refers to a hose where all components of the flexible portion of an assembly are stainless steel or any kind of corrosion-resistant metal. Similar to how we broke down hose in basic terms, a metal hose also consists of a tube...

Hose Repair: Tips to Extend Hose Life Before Buying a New One

Industrial Hose & Hydraulic Hose RepairThere are many reasons for repairing your high-quality hoses and hydraulic hoses rather than simply buying a new one. First, hoses and fittings can be expensive equipment, so repair is often a more...

Types of Hydraulic Hoses

Different Types of Hydraulic Hoses Hydraulic Hoses or Systems are everywhere, you just need to know where to look. If you see orange construction barrels, then you’re also looking at equipment littered with hydraulic systems. Zero-turn lawn mower?...

Understanding Foreign Threads in the Hydraulic Industry

Understanding Foreign Threads In The Hydraulic Industry In an ever-changing world, it is hard to ignore the increasing amount of foreign threaded connections in the hydraulic industry. Whether it is in a port connection, to a hydraulic hose, even...

Identifying the Right Hydraulic Hose for Your Application

Hydraulic hoses must be durable and long-lasting enough to handle the needs of the particular function. Hydraulic hoses, unlike many other industrial hoses, need substantial reinforcement to endure the significant pressures...