Minimum Bend Radius Vs. Force to Bend

A nominal bend radius can be easily misinterpreted as a hose’s ability to flex. When comparing two hoses with the same I.D. and minimum bend radius, you’ll find they don’t flex quite the same. Tube, cover, and reinforcement construction are the three main attributes that can determine a hose’s ability to flex. We recommend, if a hose’s ability to flex is important in your application, to get your hands on the hose to see what works for you.

Remember: Don’t confuse minimum bend radius with a hose’s ability to flex.

Teflon Tape on SAE Threads

It’s a very common misconception to believe that Teflon tape will improve any thread connection. On tapered threads it is acceptable to apply Teflon tape, but for parallel threads this is just not the case. Take JIC threads for example; the seat, or seal, is achieved on the 37-degree surface angle. On pipe thread, the seal is achieved via metal-to-metal wedging. When you apply Teflon tape to pipe thread, it lubricates the threads, also acting as an anti-seize for future maintenance.

Hose Assembly Pressure Rating

Just like a hose consisting of multiple components-tubing, reinforcement, cover-a hose assembly is a combination of multiple parts. Let’s say we’re building a 2″ assembly with 2″ stainless steel cam & grooves on each end, but it has to be 500 psi. We find a hose-Parker 7107, rated to 500 psi-perfect! However, our stainless-steel cam and groove ends are only rated to 250 psi. This means regardless of the pressure rating of the hose we specced, our assembly is only rated to safely operate at 250 psi, due to our end connections.

Let your customer know: The lowest rated component of the assembly is the max working pressure.

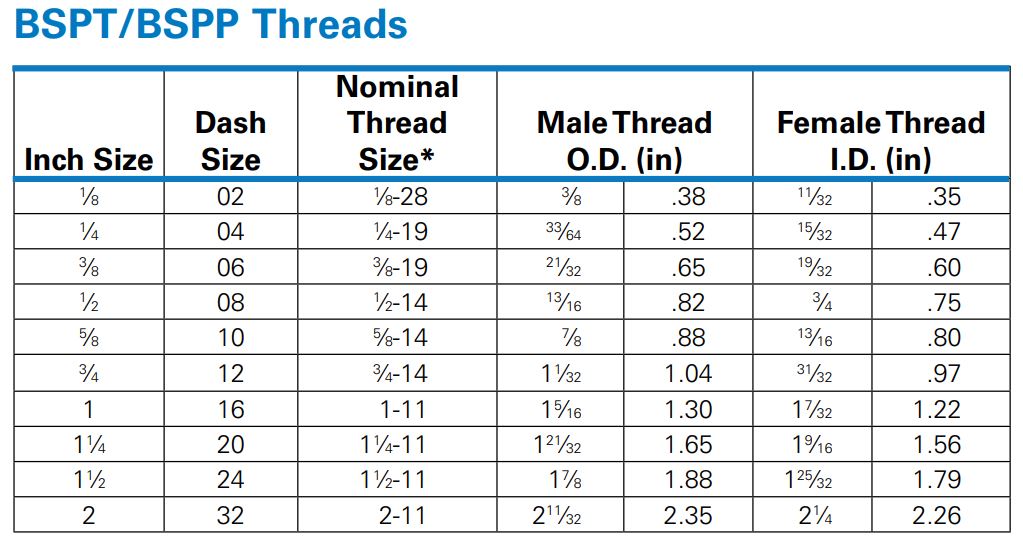

BSPP is NOT Metric

Things can get hairy when metric threads come into play. We commonly see BSPP called out as a metric thread, when someone is specifying their adapters or hose ends. However when you think about it, British Parallel Pipe is measured in threads per inch and the outside diameter is measured in fractions of an inch. Inches are not metric. Metric threads are measured in millimeters per thread and are measured by the outside diameter of the threads in millimeters.

Tubing and Hose

When talking about tubing and hose, it’s important to remember two things: hose is measured by I.D.-Inside Diameter, while tubing is measured by O.D.-Outside Diameter. Let’s say you’re brought a brake line that’s 3/8″ O.D. steel tubing. To correctly convert this to a hose assembly, you’ll want to use 3/8″ I.D. hose.

TCH Industries

Our focus and obsession is the distribution and fabrication of hose for industry and hose related products. Founded nearly 40 years ago, we are proudly owned and operated by the same family. Our manufacturing partners are some of the biggest and best names: Eaton, Parker, Dixon Valve, Hose Master, Brennen, Hannay Reels, and many others.

In short, we are a customer-centric hose company filled with happy professionals who can help you meet all your hose related needs. If you have any questions, please reach out to us by filling out the form below!