PNEUMATIC HOSE AND TUBING

What is pneumatic hose and tubing? Well, pneumatic applications are operated by air or gas under pressure. Industrial pneumatic applications are commonly powered by compressed air safety or gasses. Pneumatics can offer a simplicity in design and control, reliability, and safety over hydraulic systems. Flexible tubing and hose can provide a safe and effective means of systems operation.

WHAT IS PNEUMATIC TUBING MADE OF?

Pneumatic tubing is offered in an array of materials, the most common being rubber and plastic. Here are some of the typical tubing materials and their applications:

- Rubber: Air and water

- Plastic: Air and Water

- Aluminum: Corrosion resistance for harsh chemicals

- Brass: Plumbing applications and corrosive environments

- Stainless Steel: Ask Chris

- Steel: Ask Chris

- Copper: Corrosion resistance and heat transfer qualities

- Titanium: Corrosion resistance and lightweight properties

- Nickel: Highest temperature rating of all non-stainless steel tubing

WHAT IS THE MAIN ADVANTAGE OF USING PLASTIC TUBING IN A PNEUMATIC AIR SUPPLY SYSTEM?

Depending on the type of tubing used, such as nylon and polyethylene, some of the main advantages are price, size, weight, and ease of installation. A standard pneumatic air system won’t typically run over 150 psi, so working pressure doesn’t come into play when deciding between hose and tubing. In applications where saving space is of the essence, tubing can be a great option to run a pneumatic in tight spots, and generally weighs less than hose.

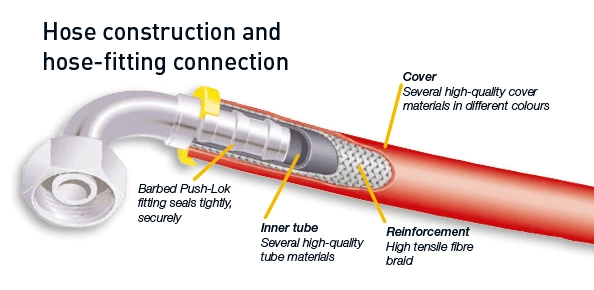

WHAT IS PNEUMATIC HOSE MADE OF?

As with pneumatic tubing, pneumatic hoses are offered with a wide range of cover and tube materials. Standard air hoses can even be offered with push to connect fittings (such as Parker’s Push-Lok), which act similarly to a Chinese finger trap. The fittings are inserted with no crimp, and the more force that is applied outwardly, the more the barbs dig into the inside of the hose. Not all hoses can be used with these fittings, so be sure to confirm Identify Air Hose Fittings with push to connect fittings. Coiled air hose assemblies are also offered in applications where kink resistant hoses may be more necessary.

Some common materials offered are:

HOSE COVER MATERIAL

- EPDM: Ethylene Propylene Diene Monomer

- Neoprene

- Nitrile

- Nylon

- PVC

- Rubber

- SBR: Styrene Butadiene Rubber

- Synthetic Rubber

HOSE TUBE MATERIAL

- EPDM: Ethylene Propylene Monomer

- Nitrile

- Nylon

- Polyurethane

- PVC

- Rubber

- Synthetic Rubber

CAN PNEUMATIC TUBING BE USED FOR WATER?

Pneumatic tubing is generally suitable for air, water, hydraulic, chemical, and refrigeration lines. As with any application, its immensely important to confirm the tubing or hose’s chemical inertness before use. Pneumatic systems run at lower pressures, typically no more than 150 psi. Even though some pneumatic tubing can have a good compatibility for hydraulic fluids, many hydraulic systems run at 3,000 psi and higher.

We Are Hosers.

Our focus and obsession is the distribution, fabrication, and manufacturing of hose assemblies for industry and hose related products. Founded nearly 40 years ago, we are proudly owned and operated by the same family. Our manufacturing partners are some of the biggest and best names: Eaton, Parker, Dixon Valve, Hose Master, Brennan, Hannay Reels, and many others.

In short, we are a customer-centric hose company filled with happy professionals who can help you meet all your hose related needs.