SELECTING THE RIGHT HYDRAULIC HOSE

TCH has a 40-year track record of helping companies with their most demanding hose assembly needs. Let’s just say we know a thing or two when it comes to selecting the right, high quality hydraulic hose for you.

Hydraulic hose is designed to provide the pressure an industrial machine needs to do is job.

When it comes to selecting the proper hydraulic hose, size, temperature, application, media, end connections, and details of your system are common considerations to make sure you get the right hose (refer to our stamped article for more information).

WHAT ARE HYDRAULIC HOSES USED FOR?

A hydraulic hose transfers pressure in a system that is doing the work, such as lifting dirt, moving a loader, or splitting logs.

WHAT SIZES DO HYDRAULIC HOSES COME IN?

We have customers coming into our shop needing a hydraulic line replaced quite frequently. In these situations. We typically see lines that are 3/8″ and 1/2″, but hydraulic hoses are available from 1/4″ all the way up to 2”.

As the I.D. (inside diameter) of hydraulic hose gets larger, you’ll start to notice a drop in PSI ratings. Take a look at the pressure ratings compared to I.D. for Danfoss Weatherhead’s H280-series hose:

| Hose | I.D. | Pressure Rating |

| H28004 | 1/4″ | 6,500 psi |

| H28006 | 3/8″ | 5,800 psi |

| H28008 | 1/2″ | 5,000 psi |

| H28010 | 5/8″ | 4,000 psi |

| H28012 | 3/4″ | 3,500 psi |

| H28016 | 1″ | 3,000 psi |

| H28020 | 1.25″ | 2,500 psi |

| H28024 | 1.5″ | 2,000 psi |

| H28032 | 2″ | 1,600 psi |

REMEMBER: These psi ratings aren’t consistent between every brand of hose, but it goes to show pretty clearly how you will lose pressure as you increase the I.D. of your hydraulic hose systems.

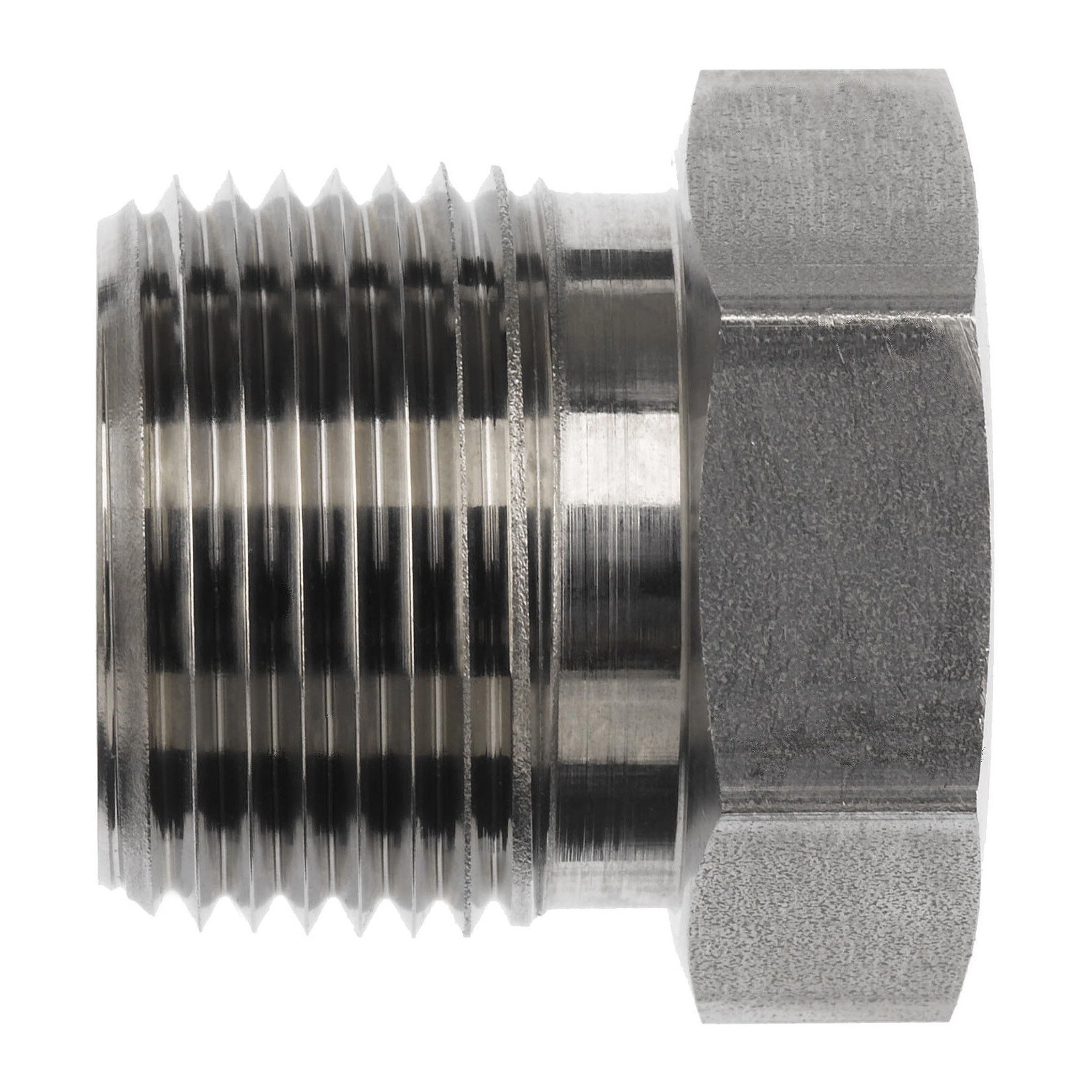

WHAT ARE THE MOST COMMON HYDRAULIC HOSE FITTINGS?

JIC (37° seat)

NPT (national pipe thread)

SAE/O-Ring Boss

O-Ring Face Seal

Metric

Code 61 & 62 Flanges

British

HOW DO I TAKE HYDRAULIC HOSES OFF?

NAHAD, The Association for Hose and Accessories Distribution, offers us insight into the proper methods of removing hydraulic hoses from an assembly.

Bearing in mind that safety should be a primary concern when removing a hydraulic hose from your system, most fittings are as simple as throwing a wrench on and loosening the end connection. Always remember to have your system depressurized, and you can save yourself a lot of trouble by having a reservoir ready for excess fluid and caps and plugs to seal off loose hoses.

Let’s review some common safety considerations:

MEDIA PERMEATION

Due to certain medias’ ability to permeate through hoses, your hose should always be used (and removed) in well-ventilated areas.

FLUID INJECTIONS

Hydraulic hoses run at very high pressures and—if it bursts—can penetrate skin and enter a human body. Fluid injections can cause severe damage and loss of limbs.

WHIPPING HOSES

If a hydraulic hose is under pressure and comes apart, the loose end can whip with strong force, and the fittings can even be blown off at high speeds. Consider using guards or restraints and remember to depressurize your system before removing a hose.

FIRE AND EXPLOSIONS FROM CONVEYED FLUIDS

As fluid passes through a hose, it can generate static electricity, resulting in static-electric discharge. The sparks generated can ignite systems or fluids in the surrounding atmosphere. You can use hose that is non-conductive in specific applications where this can be an issue.

BURNS FROM CONVEYED FLUIDS

Certain chemicals, or fluids that reach excessive temperatures, can burn human skin. Again, consider guards and shields to prevent injury.

ELECTRICAL SHOCK

Most hoses are conductive with metal fittings. Electric shock can occur when a hose assembly conducts electricity to a person.

View NAHAD’s guide for more information

We Are Hosers.

Our focus and obsession is the distribution, fabrication, and manufacturing of hose assemblies for industry and hose related products. Founded nearly 40 years ago, we are proudly owned and operated by the same family. Our manufacturing partners are some of the biggest and best names: Eaton, Parker, Dixon Valve, Hose Master, Brennan, Hannay Reels, and many others.

In short, we are a customer-centric hose company filled with happy professionals who can help you meet all your hose related needs.