Identifying Air Hose Fittings

IDENTIFYING AIR HOSE FITTINGS

From national pipe thread to various quick disconnects, there are a variety of air hose fittings that are designed to meet your specific applications needs. Regardless of your project, the professionals at TCH can help identify and determine the proper air hose fitting to suit your needs and keep your applications and operations running smoothly.

WHAT IS THE MOST COMMON AIR HOSE FITTING?

The most common air hose fittings are 1/4″ NPT with an industrial quick connect threaded on. In certain warehouses or industrial areas, where a higher CFM (cubic feet per minute) and PSI are required, 3/8″ male NPT with a quick disconnect will be more common. This metric depicts how much air will flow through your application. 3/8” hose allows much more air to flow through the hose, compared to using a 1/4″ hose. If you are constantly running an air tool or just want more power, pick 3/8”. Quick disconnects–and most standard air hose fittings such as NPT–are offered in carbon steel, stainless steel, and brass construction.

WHAT ARE THE DIFFERENT TYPES OF AIR HOSE FITTINGS?

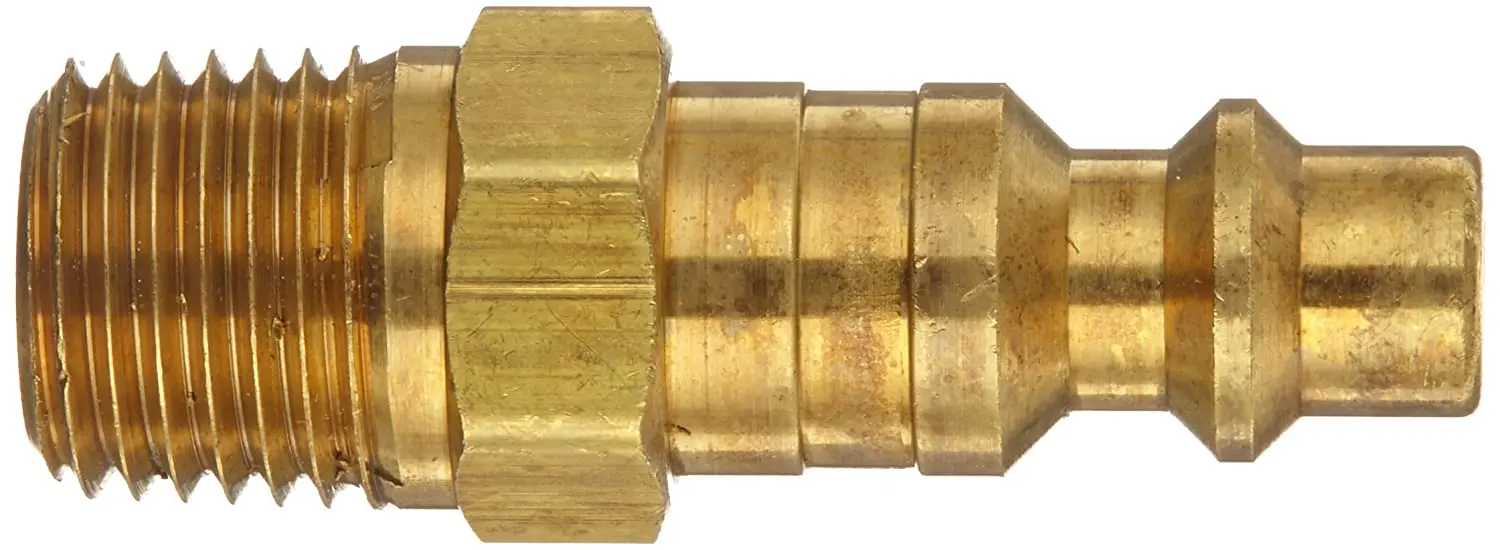

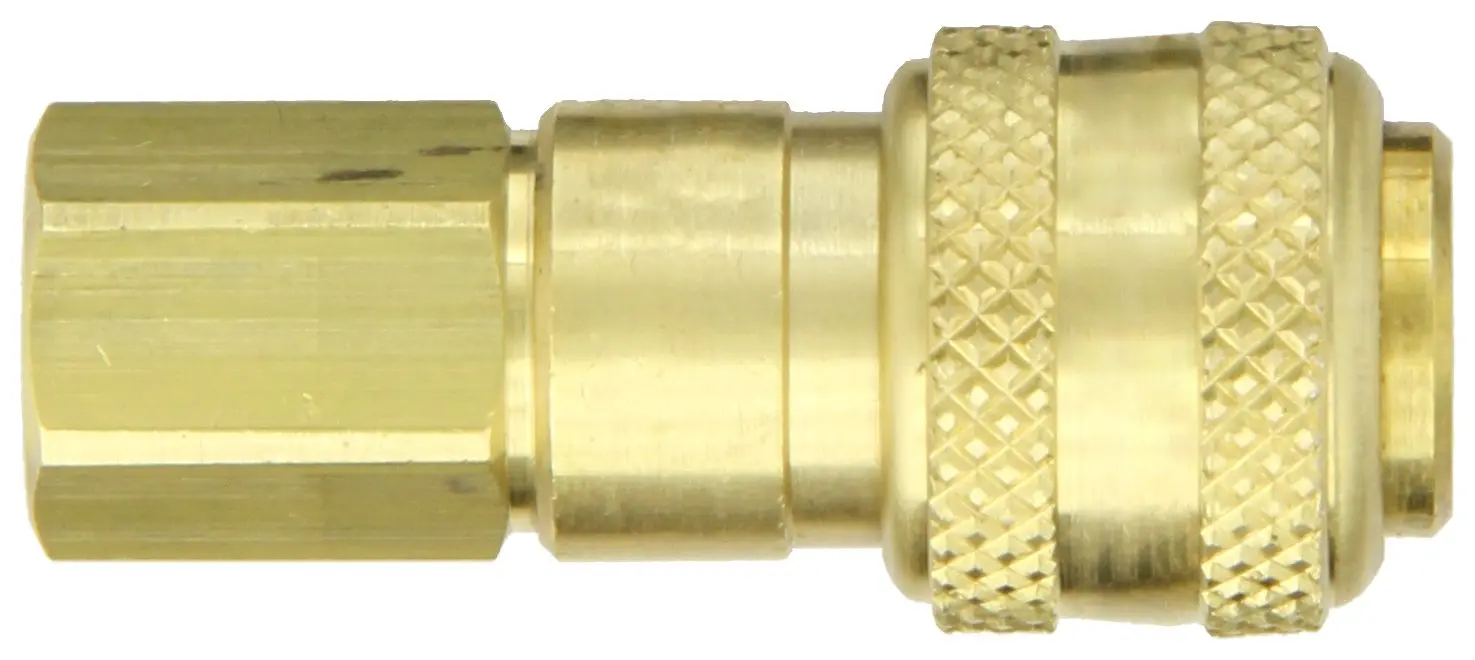

Most applications, such as air hose assemblies and air compressors will use or require a national pipe thread or quick disconnect connection. With quick disconnects, you’ll usually encounter a plug (which serves as a male end) and a coupler (serving as the female end). Don’t be surprised if you see both types of connections used in the same assembly. Many times, our hose assemblies will be built with NPT end connections in order to attach the quick disconnects.

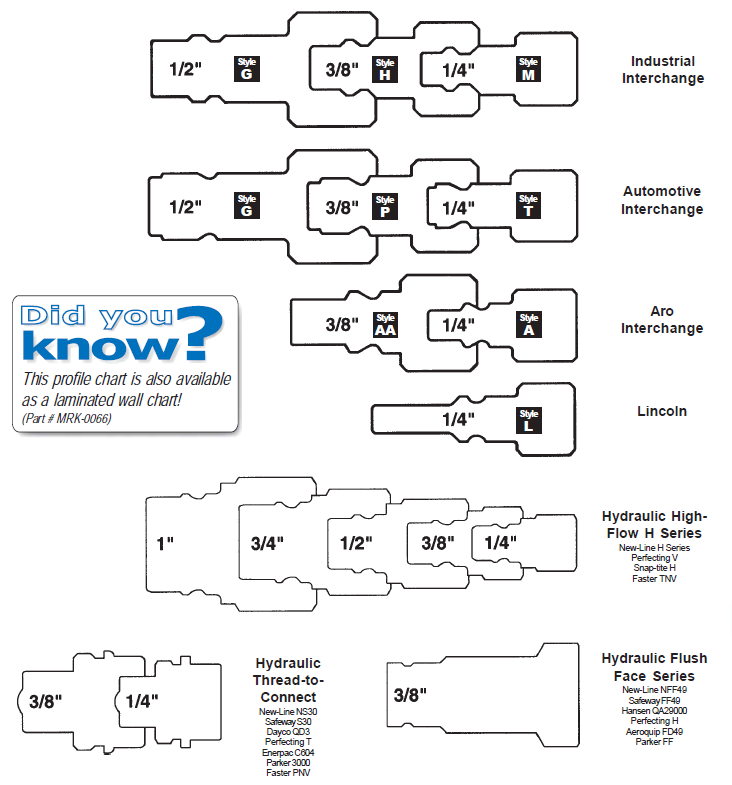

In ninety-nine percent of all applications, the quick disconnects used are industrial, automotive, and ARO.

Plug

Coupler

WHAT ARE AIR HOSE FITTINGS CALLED?

The most commonly used industry term for air hose fittings is quick disconnect (or sometimes quick connect). You’ll also hear the quick disconnects referred to as male plugs and female couplers. The four common styles are industrial, automotive, ARO, and V-style. One of the new trends in the industry is adopting a color-coded system to identify the type of fitting.

-

-

-

- Industrial: Red

- ARO: Green

- Automotive: Blue

- V-style: Purple

-

-

ARE ALL AIR HOSE FITTINGS THE SAME?

As mentioned before, air hose fittings are all different. To make sure you identify and select the proper fittings for your application, take a look at the shadow board below, or contact TCH for assistance.

WHAT IS THE DIFFERENCE BETWEEN AIR HOSE QUICK CONNECT FITTINGS?

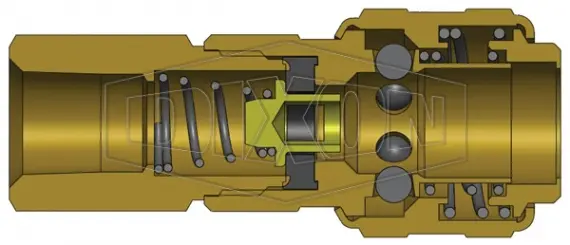

Although each style of air hose quick connect fitting has its own specific style, the biggest difference is where the stainless-steel bearings of the quick connect coupler locks into the groove on the nipple. Even though some series have similar body types, the coupler will not lock into place because of the position of the bearings. You may also notice some small differences in the CFM flow rate versus PSI drop, but it normally isn’t enough to be concerned with.

CAN YOU USE AIR HOSE FITTINGS FOR WATER?

Short answer: No

You should not use any air specific item for a water application. Doing so can significantly damage your equipment due to residual water. Any pneumatic quick disconnect is not going to be recommended to, or rated for, use on a water application.

That being said, there are times–if you’re in a pinch–where you might be able to get away with using an air fitting for a water application. But you should immediately replace them with new ones after doing so. For water applications, the E-series quick disconnect is more appropriate, because of its straight-through design. Make sure to speak with a professional at TCH to determine if this is appropriate for your application.

HOW ARE AIR HOSE FITTINGS MEASURED?

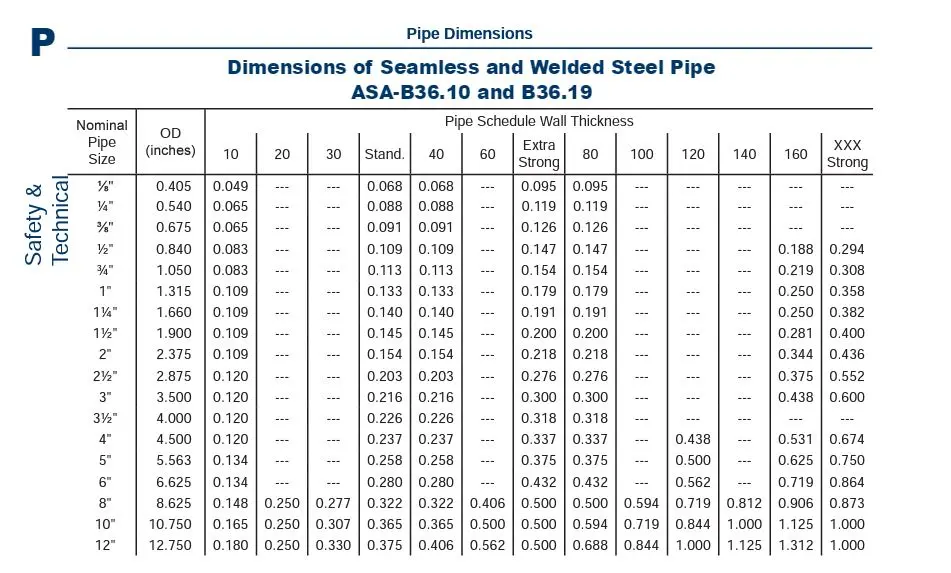

To answer this question, we need to go back to the original question of types of connections. If our application is NPT, it is measured by the nominal size. A good rule of thumb is to measure the outside diameter of the male threads and subtract ¼”. This is the part’s nominal size. If it’s a quick disconnect, however, it will be measured by the nominal body size.

HOW MUCH PSI DO I NEED TO CLEAN CONCRETE?

We could say this for almost any question asked, certain situations you face are going to require different answers. However, the general rule of thumb is that 3,000 PSI, with a flow rate of 4 gallons per minute, is the recommended pressure to clean concrete.

HOW TO STOP AIR HOSE FITTINGS FROM LEAKING?

Our first step in stopping an air hose fitting from leaking is to find and identify the leak point. If the application is leaking from the threads, you can always try Teflon tape, pipe dope, or thread sealant, and then torque your thread down tighter. If you’re leaking from the quick disconnect, it is normally easier and more cost effective to just purchase a new one, compared to repairing your current quick disconnect.

A lot of times, in our retail store, we also run into hose assemblies that have burst just behind the fitting. In these situations, TCH is always more than happy to cut off the end and crimp a new fitting on to your air hose assembly. If the hole isn’t close enough to the end (or if you can’t afford to lose length on your assembly, we will also cut the hose where the hole is and create a union wherever is needed to get you up and running.

AIR HOSE FITTING SAFETY

When working with air hose fittings and compressed air systems, it is deemed safe and effective up to the working pressure of the assembly. It may seem obvious, but maintaining and checking your systems before and after use can help avoid unnecessary mistakes. Remember to check your connections and for cuts or holes in hoses before operation, and make sure to not leave loose hose lying around after use.

As with any application, ensure that the quick connects and hoses that are being used on your application meet the requirements—such as pressure rating—for your application.

We Are Hosers.

Our focus and obsession is the distribution, fabrication, and manufacturing of hose assemblies for industry and hose related products. Founded nearly 40 years ago, we are proudly owned and operated by the same family. Our manufacturing partners are some of the biggest and best names: Eaton, Parker, Dixon Valve, Hose Master, Brennan, Hannay Reels, and many others.

In short, we are a customer-centric hose company filled with happy professionals who can help you meet all your hose related needs.