As simple as it seems, there is a right way to apply Teflon tape. Doing so can ensure your fittings seal properly and your connections won’t leak.

The Right Way to Apply Teflon Tape

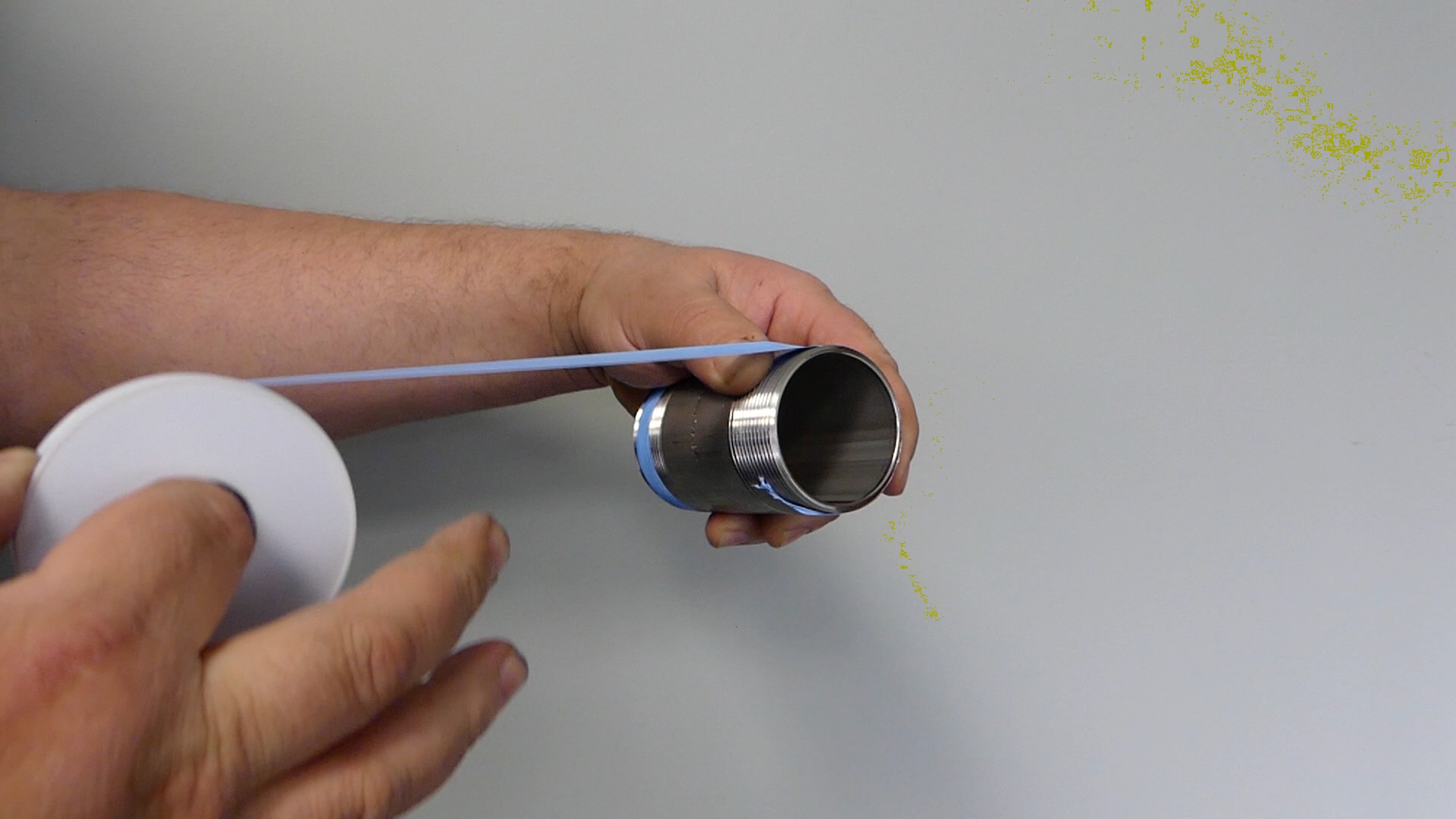

When you begin the application, start the tape on the second thread and apply clockwise. Doing so will help prevent cross threading and ensure tape does not end up inside the pipe. Once you have your proper placement, keep the tape tight and continue wrapping three times.

A standard pipe fitting will seal properly after you have threaded it in about a half an inch or so, depending on the size. Because of this, the most commonly used thread tape is half of an inch in width. Keep this in mind when applying the proper amount of plumbers tape and let this serve as a starting point on how far to thread in your pipe fittings.

How to apply Teflon tape clockwise

You may find yourself asking ‘how do you apply thread tape clockwise’? Once you know how, it’s pretty simple. Hold the thread in your hand and aim it at your eyes. While looking at the thread from this perspective, apply the tape in a clockwise manner.

The Wrong Way

As easy as it may seem, there are wrong ways to apply tape to pipe threads. As mentioned before, don’t cover the first thread. Doing so can lead to pieces of the thread seal tape contaminating your system. Also, if the tape is applied counter clockwise it will functionally unwind as the part is threaded together. Clockwise helps the tape to tighten as it is threaded together

When Do You Use Teflon Tape?

Teflon tape is a standard for many different applications. These include air fittings, natural gas lines, propane, water, and plumbing, just to name a few. Occasionally you will see a color-coded system for more volatile applications. Yellow is used for gas pipe fittings where natural gas is involved, whereas green is for oxygen lines and applications. Being virgin Teflon, green tape contains no oil or contaminants. This helps to prevent combustion from happening.

When Not to Use Teflon Tape?

There are many instances of Teflon tape being used on improper applications. For example, many hydraulic fittings such as JIC are seen with thread tape. However, the seal on a JIC connection is formed on the 37° metal to metal cone seat and not on the threads. PTFE tape doesn’t help with this seal and can create unnecessary leak points, not to mention the possibility that it will contaminate your hydraulic system.

Conclusion

Think about your connections before applying Teflon tape. Ask yourself if the seal is made via threads or another method, such as an O-ring or compression. This can help make sure you only apply thread tape where appropriate.

Plastic fittings, as opposed to metal pipe, are another great example of when to be careful about your usage of Teflon tape. The tape acts to reduce friction and makes it easy to over torque. Because plastic is fragile, over torqueing can cause the fitting to crack.

TCH Industries offers a wide variety of Teflon tape, including higher density tapes.

Keep these tips in mind when you ask yourself how to apply Teflon tape, and you’ll have your connections more secure than ever before!

We Are Hosers.

Our focus and obsession is the distribution, fabrication, and manufacturing of hose assemblies for industry and hose related products. Founded nearly 40 years ago, we are proudly owned and operated by the same family. Our manufacturing partners are some of the biggest and best names: Eaton, Parker, Dixon Valve, Hose Master, Brennan, Hannay Reels, and many others.

In short, we are a customer-centric hose company filled with happy professionals who can help you meet all your hose related needs.