Pressure Washer Hose

Pressure Washer Hose

When the weather warms and the snow melts, the season for pressure washing is pushed off in full force and the need for pressure washer hose. Which is why the professionals at TCH Industries are stocked, locked, and loaded to get you informed and stocked up on the best pressure washer hose for the season to keep your business functional and efficient. Whether you have a gas pressure washer or an electric pressure washer, TCH Industries has the right parts to get the job done the first time!

HOW LONG CAN A PRESSURE WASHER HOSE BE?

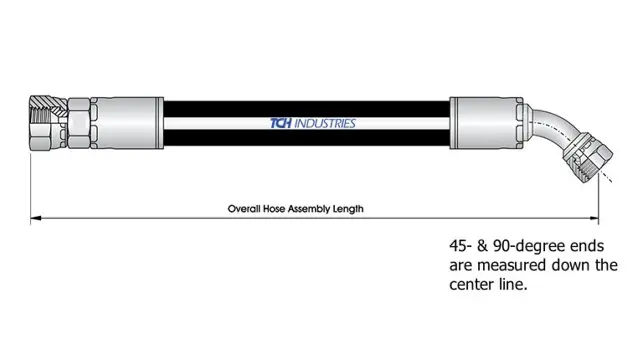

To keep a long story short—or a short hose long—the easy answer is that your pressure washer hose can be whatever length is needed. We typically supply our assemblies in twenty-five-, fifty-, and one-hundred-foot lengths with ends and bend restrictors included.

That being said, there are options, such as straight-through quick disconnects to extend the length of your assembly or even allow you to easily connect 2 hoses together. When you need to park in the front of the house, we can ensure you have ways to extend your assembly from the hose reel in your truck to your customer’s backyard.

DO YOU LOSE PRESSURE WITH A LONGER HOSE?

There are many considerations when learning how the length of the hose can impact the pressure rating of your assembly. In a best case scenario, when working in normal operating conditions on flat ground, the drop in pressure per extended length of hose is not significant. We all know that operating conditions are very rarely normal, and we often find ourselves working in unique environments.

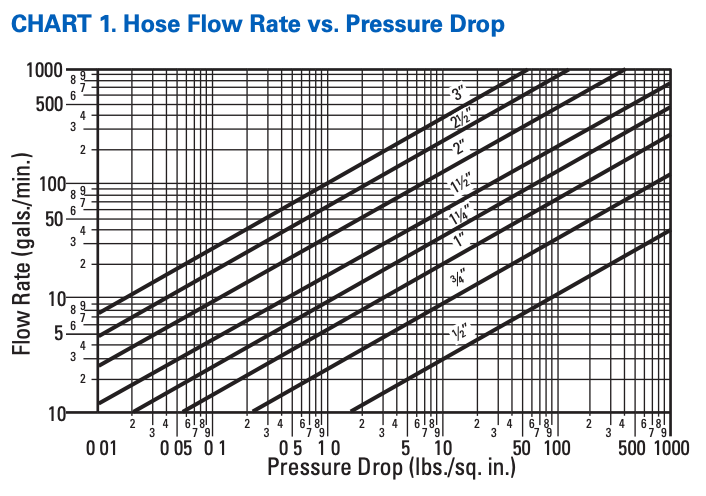

The chart below from Danfoss Weatherhead will elaborate more on these drops in pressure. As you will see, the friction between the water and the hose is exponentially increased as the length of the hose is increased. This is what leads to pressure loss in a hose assembly.

CAN YOU CONNECT TWO PRESSURE WASHER HOSES TOGETHER?

The simple and short answer is yes. But you’ll need the right equipment to do it efficiently, and with minimal pressure loss. If you ever find yourself in a situation where your setup doesn’t grant the length you need for the job, that doesn’t always mean you need to purchase an entirely new assembly. As we mentioned before, we offer straight-through quick disconnects to connect more than one assembly to help get the job done right!

ARE POWER WASHER WANDS UNIVERSAL?

As with many products in the industry, we see many proprietary accessories and fittings that can’t easily or safely be replicated. The same can be said for power washer wands. Depending on your application and the pressure washer gun your using, you may be required to use wands and attachments made specifically for your equipment. Because of this, TCH Industries strives to stock a wide variety of power washing attachments to fit your application.

WHAT SIZE ARE PRESSURE WASHER FITTINGS?

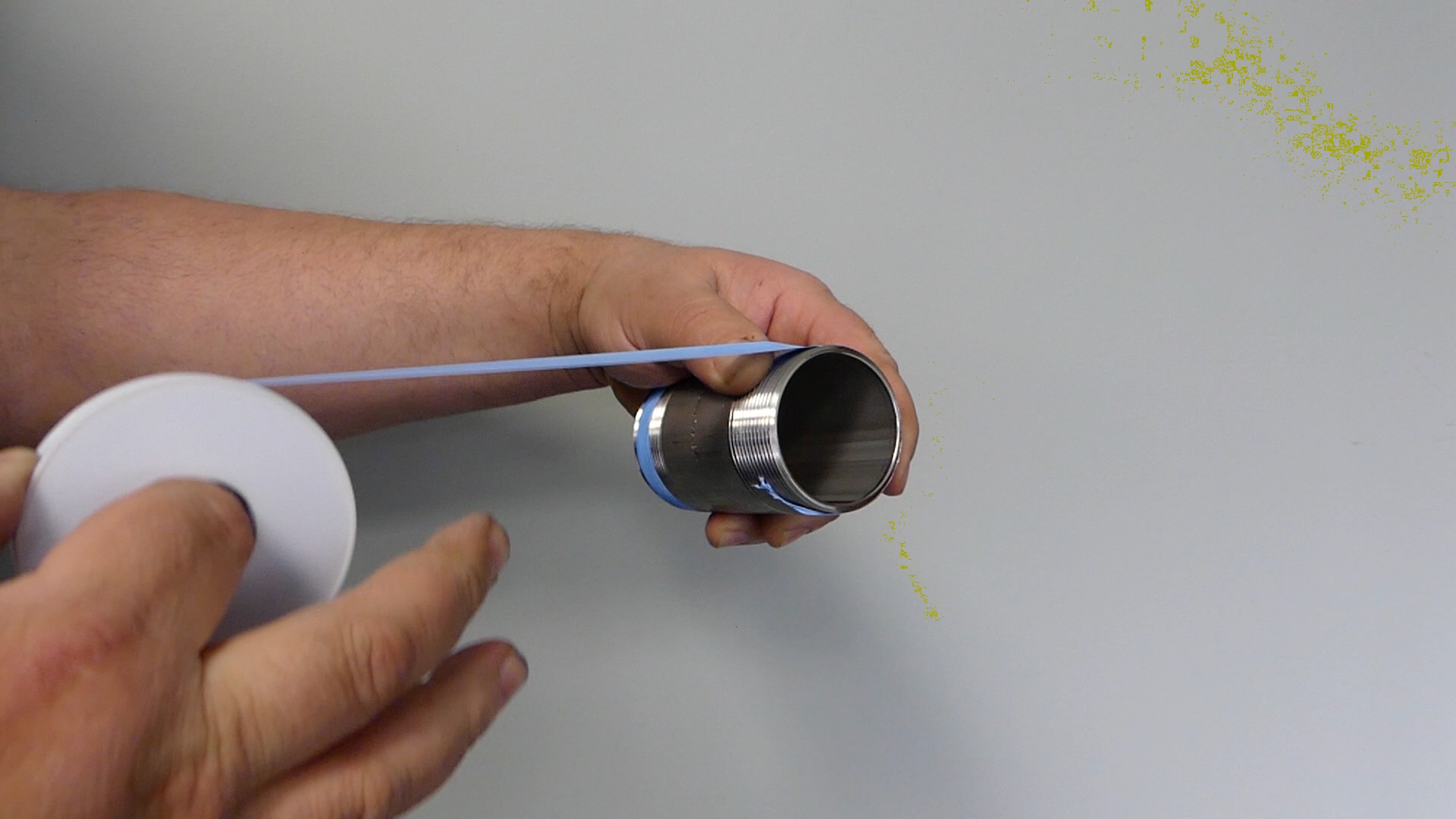

Many of the ends, adapters, and quick disconnects that we supply with our assemblies are 3/8″. Which is why TCH Industries’ PowerKlean4000 pressure washer hose with a 3/8” inside diameter.

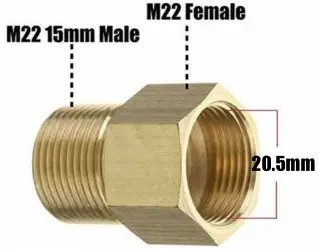

In the pressure washing industry, it is very common to see metric M22X1.5 threads. The outer diameter is 22 millimeters, with a metric 1.5 thread count, on the male end.

However, the female end has an inside diameter of 20.5 millimeters, but still has the metric 1.5 thread pitch, and generally has an O-ring to prevent leaking. These threads are common on pumps, hoses, and spray guns. And normally have a black plastic nut on the female end. With the right adapter, these can easily be couple with quick connect fittings.

CAN YOU USE A 100-FOOT GARDEN HOSE ON A PRESSURE WASHER?

It all depends on if you are using it for the inlet or outlet of the pressure washer.

If you are using it on the inlet side, the answer is yes you can use a 100 ft garden hose. But there are going to be some drawbacks compared to using a shorter hose. As mentioned before, a longer hose will slowly begin to decrease water pressure. Which may lead to starving the pump of water. This will lead to a reduction in the water on the outlet end and may even damage the pump.

If you are using a garden hose on the outlet, or pressure side, the answer is a very big NO! Pressure washers operate at a much higher PSI than a standard garden hose is rated for. Doing can, and more than likely will, lead to the hose bursting once it becomes filled with water. As a result, this can lead to increased down time or even injury.

We recommended using a 3000 psi, 4000 psi, or 4500 psi power washer hose. These high-pressure hoses will make sure you get the job done right the first time. TCH Industries’ PowerKlean 4000 hose is a kink resistant, non-marking, abrasion resistant, and steel wire braided reinforced. Which is perfect for pressure washing replacement hoses.

HOW MUCH PSI DO I NEED TO CLEAN CONCRETE?

We could say this for almost any question asked, but it’s the truth. Certain situations you face are going to require a different answer. However, the general rule of thumb is that 3,000 PSI, with a flow rate of 4 gallons per minute, is the right pressure to clean up concrete.

HOW DO I PRESSURE WASH WITHOUT A PRESSURE WASHER?

Pressure washing without the added PSI of a pressure washer defeats the purpose. However, we do have a few options to give a similar effect. Wand attachments can be used to restrict flow. Which will increase the velocity of the water coming out of the wand. Take the reference below for example.

When you turn on your water to your garden hose, with nothing covering the end, it will simply flow out at a low velocity. Which is why the water flows out of the orifice and does not go very far. But once you put your thumb over the end, the water shoots much further.

It’s easy to think that the PSI has somehow magically increased dramatically by doing this. But the answer is that the PSI has remained the same, you just reduced the orifice size that the water comes out from. This leads to a dramatic increase in the velocity of the water, which is why it shoots out much further.

You can use the wand attachments to get a similar effect. With the right attachments, you can also change out the nozzle tips for different angle while spraying.

WHAT PSI IS SAFE FOR WASHING CARS?

Power washing cars is a safe and effective way to get your (or your customer’s) vehicle in pristine condition. But unlike other applications, you need to be more mindful of pressure ratings when using your pressure washer on a vehicle.

If you use a 3000-PSI—or higher— pressure on a vehicle, you can easily damage the paint. For these jobs, you’ll want to stay closer to the 1000 – 2000 PSI range. The majority of pressure washers have a pressure reducing valve, which will need to be adjusted accordingly.

HOW MUCH PSI IS A GARDEN HOSE NOZZLE?

Typical garden hose nozzles are rated for 200 PSI. TCH offers a wide variety of nozzles, with higher end models that can reach 400 PSI before bursting. But just because your nozzle is rated to 400 PSI your hose may not be. This is a very easy misconception in the fluid flow industry. Make sure you contact the professionals at TCH Industries to get the right nozzle for your assembly.

We Are Hosers.

Our focus and obsession is the distribution, fabrication, and manufacturing of hose assemblies for industry and hose related products. Founded nearly 40 years ago, we are proudly owned and operated by the same family. Our manufacturing partners are some of the biggest and best names: Eaton, Parker, Dixon Valve, Hose Master, Brennan, Hannay Reels, and many others.

In short, we are a customer-centric hose company filled with happy professionals who can help you meet all your hose related needs.